Rainwater Tanks and Pumps

Poly is the best material for a rainwater tank and Yarrin makes Australia’s best poly water tank

While it might not be obvious, good engineering and build quality is vital for two main reasons:

1. Sitting outside and exposed to the elements, poly tanks expand and contract due to temperature. In addition, the weight of water in the tank pushes outwards and downwards, and the pressure the water exerts changes with the water level in the tank. Over time, the continual expansion and contraction exploits any weakness in the product and can result in a crack.

2. The weight of the water exerts more pressure at the bottom of the tank than at the top, and this causes the base of the tank to bulge. The bulging increases the circumference more at the base of the tank and decreases towards the top. While this bulging is barely noticeable to the human eye, the pressure pushing the side of the tank outwards also has the effect of pulling the roof downwards.

In poorly engineered tanks, the effect of pulling the roof downwards could eventually lead to a partial or complete failure of the roof, and without bracing of the roof, the entire tank could collapse.

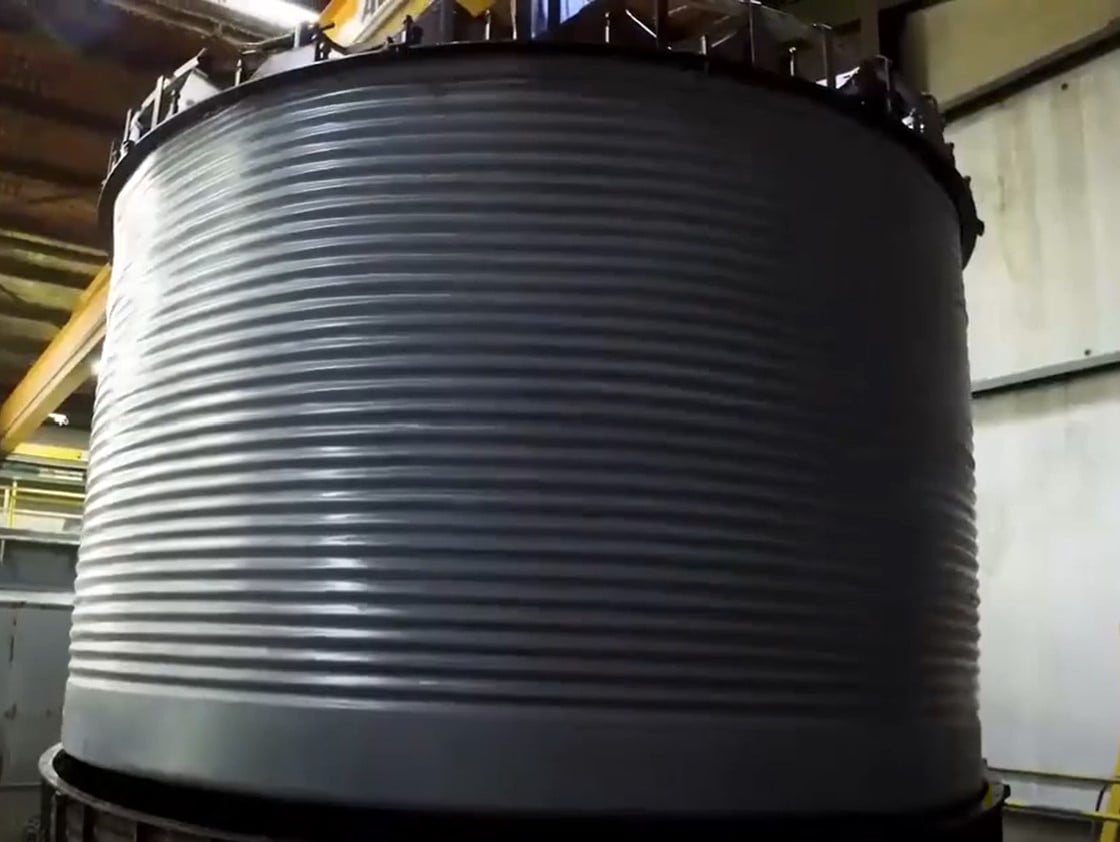

While the corrugated design of Yarrin tanks is attractive, its main benefit is extraordinary strength of the tank wall design which, when integrated with the Crown ForceTM roof profile, with its triangular roof beams, creates unprecedented rigidity and strength.

Yarrin are one of only a handful of tank manufacturers that blend their own raw materials and have complete control over the end-to-end manufacturing process.

The raw material used in the fabrication of Rapid Plas water tanks is RGBlend 20 - a proprietary combination of product and processing that is perfectly aligned with the tank manufacturing process. The combination of RGBlend 20 and Rapid Plas’ relentless attention detail throughout the entire process results in a water tank of superb quality.

Poly rainwater tanks are manufactured by a process called cooking and Yarrin have been cooking poly rainwater tanks for over 30 years.

When cooking a rainwater tank, the raw materials are placed in a mould that is heated and rotated. The raw material melts, creating a slurry, and the rotation, air and controlled heating combine to distribute the slurry precisely throughout the mould. The quality of the ingredients, the consistency of the blend, the cooking time, air pressure and temperature, dictate how the raw materials are distributed throughout the finished product, and all have a profound impact on tank quality.

Once the slurry has been accurately placed within the mould, it is carefully cooled to a defined temperature before being opened to reveal the seamless, single-piece water tank.

A budget tank manufacturer that buys pre-blended raw materials does not control all the production variables and is rolling the dice in terms of quality of output, and the consumer bears the risk of potential flaws or weaknesses in the finished product that might result in product failure.

Rapid Plas have been manufacturing superb quality poly rainwater tanks in Tamworth for over 30 years. Incorporating the most up-to-date engineering, manufacturing, and chemistry, Yarrin are Australia’s best-ever poly water tanks and offer a new era in rainwater storage.